The mesh belt drying furnace has the function of automatic loading, carburizing,nitriding, quenching and tempering and drying etc.

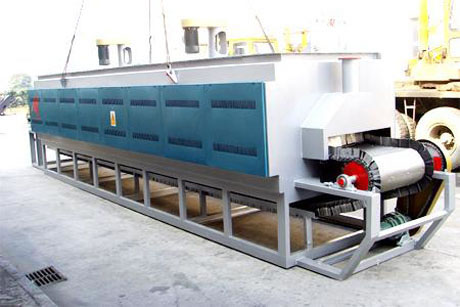

Mesh Belt Drying Furnace Introduction

Mesh Belt Drying Furnace which is also called Mesh Belt Heat Treatment Furnace, can be used for the heat treatment of mechanical parts such as fastening parts, chains,bearings,automobile fittings, auto Parts and mechanical parts for tools etc.

The mesh belt drying furnace has the function of automatic loading, carburizing,nitriding, quenching and tempering and drying etc.Baika is able to design non-standard mesh belt heat treatment furnace as per customers' requests. And exported the furnace to many countries, for example, Vietnam,Indonesia, Russia, Pakistan, India, Mexico, Egypt, etc.

The main features of the mesh belt drying oven include high efficiency, continuity, energy saving, and easy control. It uses steel mesh as a conveyor belt to carry materials for continuous drying, suitable for various industries such as metallurgy, building materials, ceramics, fertilizers, chemical industry, etc.

It adopts advanced hot air circulation technology, it can quickly evaporate the moisture in the material, shorten the drying time, and improve the drying efficiency;

The furnace can work continuously without stopping to achieve batch production, suitable for large-scale production needs;

The mesh belt structure allows the material to be uniformly heated, avoiding local over drying or over wetting, ensuring consistent product quality;

The furnace has advanced control systems can achieve automated control and remote monitoring, making it convenient to use and manage;

The mesh belt drying furnace has strong processing capacity, which can process a large amount of materials in a short period of time, improve production efficiency, and reduce the production cost;

When the furnace start running, through reasonable hot air circulation and material transfer design, the moisture in the material is quickly removed, shortening the production cycle;

Drying efficient

Flexible configuration

Uniform drying

Energy conservation and environmental protection

Flexible control

Large processing capacity

Fast drying speed

High evaporation intensity

|

Model |

BKW-40-5 |

Remark |

|

Voltage |

380V |

Customized |

|

Frequency |

50Hz |

Customized |

|

Phase |

3 phase |

|

|

Rated power |

30kw |

|

|

Limit temperature |

500℃ |

Adjustable |

|

Working dimension |

L3000×W800×H120mm |

Customized |

|

Feeding platform |

1000mm |

Customized |

|

Discharge platform |

800mm |

Customized |

|

Number of temperature control zones |

1 zone |

Can be individually temperature controlled or Customized |

|

Heating element |

0Cr25Al5 |

Alloy wire |

|

Temperature control instrument |

Power controller control, temperature control instrument adopts Japanese Fuji intelligent instrument, PID control with over temperature alarm function, and the control panel is equipped with voltage and current meters and operation buttons. |

|

|

Transmission mechanism |

Adopting variable frequency speed regulation |

|

|

Mesh belt material |

Made of stainless steel and chain belt type |

|

|

Install smoke exhaust hoods in front and behind the furnace respectively |

|

|

Please feel free to leave a message. We will reply you in 24 hours.

BAI KA Copyright © 2025 ALL rights reserved